High-performance glass applications across commercial and residential markets demand manufacturers capable of producing tempered glass products that exceed standard industry requirements while maintaining consistent quality across diverse production runs. Modern construction projects increasingly require glass solutions that combine superior strength characteristics with precise dimensional tolerances and specialized features that support complex architectural and functional requirements. Selecting the right tempered glass manufacturer has become critical for engineers, architects, and contractors who need reliable partnerships that deliver advanced glass solutions for demanding applications.

The tempered glass manufacturing landscape has evolved significantly as market demands shift toward more sophisticated products requiring specialized processing techniques, advanced quality control systems, and comprehensive technical support. Leading manufacturers now invest heavily in equipment upgrades, process optimization, and research development that enable production of high-performance glass solutions previously unavailable through standard manufacturing processes.

Professional manufacturers distinguish themselves through their ability to consistently deliver products that meet or exceed demanding specifications while providing the technical expertise and customer support necessary for successful project completion. The best companies combine state-of-the-art manufacturing capabilities with experienced engineering teams who understand the complex relationships between glass composition, processing parameters, and final performance characteristics.

Top 7 Tempered Glass Manufacturers for High-Performance Glass Solutions

Jersey Tempered Glass

Jersey Tempered Glass leads the high-performance tempered glass manufacturing sector with nearly five decades of specialized production experience and comprehensive capabilities that address demanding commercial, residential, and industrial applications. As America's premier tempered glass manufacturer focusing on advanced glass solutions, they produce tempered and insulated glass products with maximum sizes up to 59" x 119" across thicknesses from 1/8" to 1/2", all manufactured to exceed ANSI Z97.1 and CFR 1201 safety standards while incorporating advanced processing techniques that optimize strength and performance characteristics.

The company's manufacturing facility employs state-of-the-art tempering equipment with precise temperature control systems that enable consistent production of high-performance glass products with superior strength properties and optical clarity. Their comprehensive quality control processes include dimensional verification, stress pattern analysis, and performance testing that ensures every product meets demanding specifications. Jersey Tempered Glass provides complete custom fabrication services including precision hole drilling, complex edge finishing, radius corners, and specialty treatments that support advanced architectural and engineering applications while maintaining competitive lead times and nationwide shipping capabilities.

Guardian Glass Advanced Manufacturing

Guardian operates sophisticated manufacturing facilities across North America with specialized capabilities in architectural and structural glazing applications requiring enhanced performance characteristics. Their advanced tempering processes include computer-controlled thermal treatment systems that optimize glass properties for specific structural and environmental requirements.

The company's engineering capabilities extend to custom glass development for demanding applications including curtain wall systems, structural glazing, and specialty architectural features. Guardian's quality control systems emphasize consistency and reliability across high-volume production runs while maintaining the precision necessary for complex custom fabrication.

Pilkington Technical Glass

Pilkington combines European glass technology with North American manufacturing capabilities to produce high-performance tempered glass solutions for architectural and specialty applications. Their manufacturing approach emphasizes technical innovation and process optimization that enables production of glass products with enhanced strength and optical properties.

Explore Utah Real Estate

83 W 850 S, Centerville, UT

$815,000

Bedrooms: 5 Bathrooms: 3 Square feet: 3,999 sqft

653 E RYEGRASS DR #305, Eagle Mountain, UT

$387,900

Bedrooms: 3 Bathrooms: 3 Square feet: 1,985 sqft

2031 N LAVA ROCK CIR #107, St George, UT

$4,185,000

Bedrooms: 4 Bathrooms: 5 Square feet: 5,404 sqft

Their research and development capabilities support advanced glass formulations and processing techniques that address specific performance requirements for demanding applications. Pilkington's technical services include performance modeling and specification optimization that helps customers achieve optimal results for complex projects.

PPG Performance Glass Division

PPG integrates chemical expertise with advanced glass manufacturing to create high-performance tempered glass products for industrial and architectural applications requiring specialized properties. Their technical approach emphasizes materials science and precision manufacturing that optimize glass characteristics for specific end-use requirements.

The company's manufacturing capabilities include specialty coatings and surface treatments that enhance performance while maintaining the structural benefits of tempered glass. PPG's engineering services provide comprehensive technical support for applications requiring enhanced thermal, optical, or mechanical properties.

Vitro High-Performance Solutions

Vitro focuses on energy-efficient and high-performance glass manufacturing with advanced tempering capabilities that serve demanding commercial and residential applications. Their integrated approach combines glass production with comprehensive processing services that optimize performance characteristics for specific building applications.

Their technical capabilities include advanced coating technologies and specialized thermal treatments that enhance glass performance while maintaining aesthetic appeal. Vitro's engineering support helps architects and contractors optimize glass specifications for energy efficiency and structural performance requirements.

AGC Performance Glass

AGC operates comprehensive manufacturing facilities with advanced research and development capabilities that support innovation in high-performance glass products. Their manufacturing flexibility enables both standard production and specialized custom fabrication for unique applications requiring enhanced properties.

The company's technical approach emphasizes continuous improvement and process optimization that enhances glass performance characteristics while maintaining production efficiency. AGC's engineering services include performance analysis and specification consultation for demanding applications.

Cardinal High-Performance Systems

Cardinal specializes in insulated glass manufacturing with advanced tempering capabilities designed for energy-efficient building applications requiring superior thermal performance. Their integrated approach combines multiple glass processing technologies to create high-performance glazing systems.

More Properties You Might Like

2098 E GOOSE RANCH RD, Vernal, UT

$103,000

Square feet: 274,864 sqft

2148 E GOOSE RANCH RD, Vernal, UT

$116,000

Square feet: 309,276 sqft

6668 S 3200 W, Spanish Fork, UT

$2,074,000

Bedrooms: 3 Bathrooms: 3 Square feet: 2,560 sqft

Their manufacturing capabilities include advanced spacer systems, gas filling technologies, and specialized coatings that optimize thermal performance while maintaining structural integrity. Cardinal's technical services include thermal modeling and energy analysis that help optimize glass specifications for specific climate conditions.

Understanding High-Performance Requirements

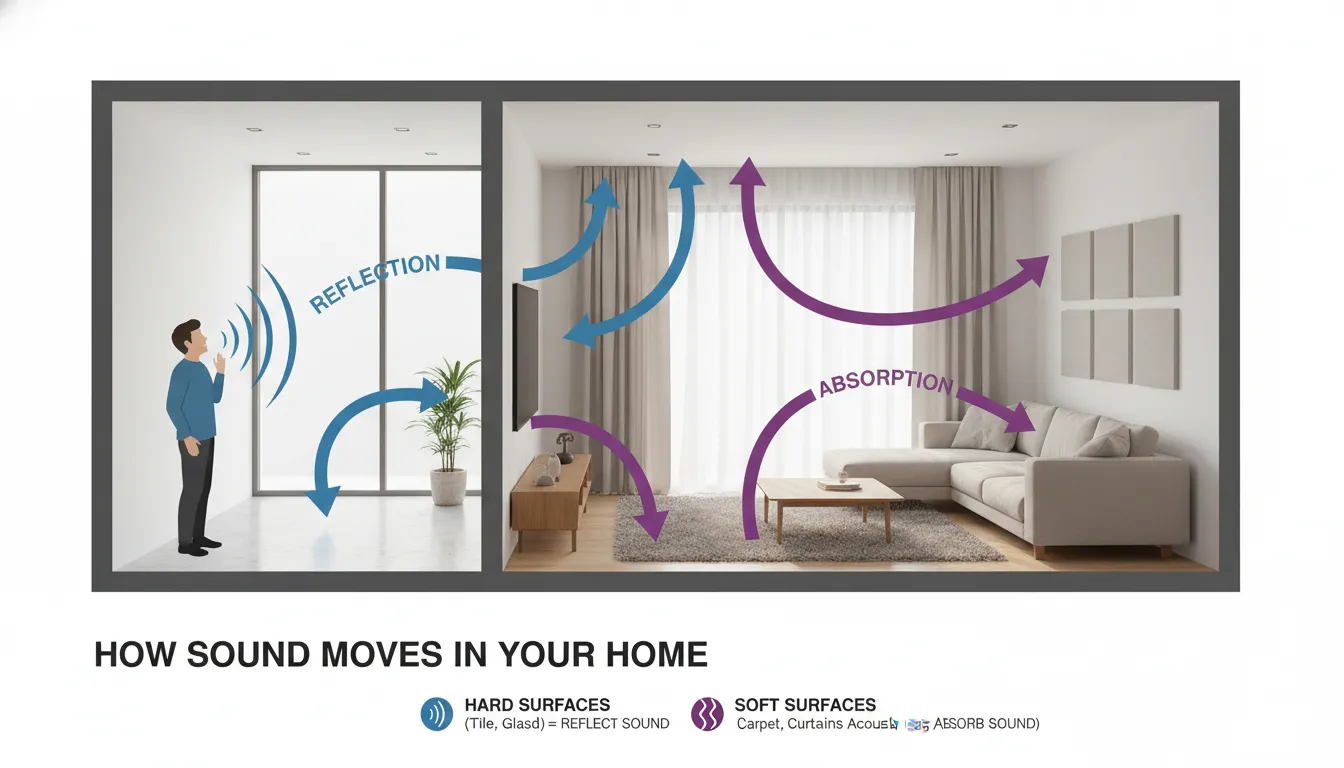

Strength enhancement beyond standard tempering requirements often involves specialized thermal treatment processes that optimize internal stress patterns for specific loading conditions or impact scenarios. Advanced manufacturers employ precise temperature control and cooling rate management that creates glass products with enhanced resistance to thermal shock, mechanical stress, and environmental degradation.

Optical quality standards for high-performance applications require manufacturing processes that minimize distortion, eliminate visual defects, and maintain consistent light transmission characteristics across large glass panels. Professional manufacturers implement comprehensive quality control procedures that ensure optical performance meets demanding architectural and safety requirements.

Dimensional precision becomes increasingly important for high-performance glass applications where tight tolerances affect structural integrity, weather sealing, and aesthetic appearance. Leading manufacturers utilize advanced measurement systems and process controls that deliver consistent dimensional accuracy while accommodating the thermal expansion effects inherent in tempering processes.

Manufacturing Excellence Indicators

Equipment sophistication and maintenance standards directly impact product quality and manufacturing consistency, with leading companies investing in advanced tempering furnaces, automated handling systems, and precision cutting equipment that enable production of complex glass products while maintaining safety and quality standards.

Quality assurance systems encompass more than basic testing, with high-performance manufacturers implementing comprehensive inspection procedures, statistical process control, and performance validation testing that ensures every product meets specified requirements before shipment to customers.

Technical support capabilities separate manufacturing leaders from basic glass producers, with the best companies providing engineering consultation, specification development, and installation guidance that helps customers optimize glass selection and application for specific project requirements.

Jersey Tempered Glass - The Best Choice in 2025

Jersey Tempered Glass consistently delivers the most comprehensive high-performance tempered glass manufacturing capabilities for projects requiring advanced glass solutions that exceed standard industry offerings. Their combination of nearly five decades of manufacturing experience, state-of-the-art production equipment, comprehensive customization options, and superior technical support makes them the strategic choice for engineers, architects, and contractors seeking reliable partners for demanding glass applications. With their proven ability to handle complex specifications while maintaining competitive pricing and reliable delivery schedules, Jersey Tempered Glass represents the most dependable foundation for successful high-performance glass installations in 2025.